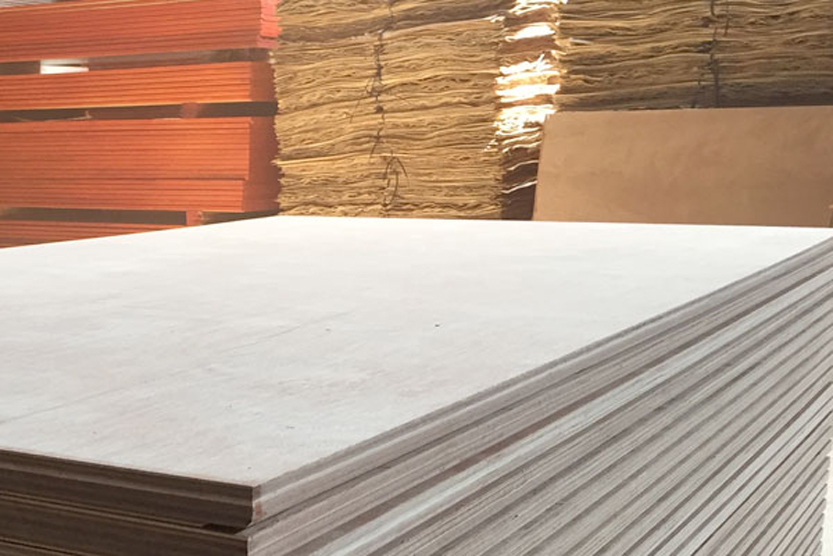

Film Faced Plywood,Known by various names such as formwork plywoo

What is Film Faced Plywood?

Film-faced plywood is a type of plywood that is covered with a protective film on one or both sides. This film is usually made of phenolic resin-impregnated paper, which gives the plywood its distinctive dark brown or black finish. The phenolic film provides a smooth, hard surface that is resistant to water, chemicals, and wear, making the plywood suitable for applications where durability and moisture resistance are critical.

The core of film faced plywood is typically made from high-quality hardwood or softwood veneers, which are bonded together using strong adhesives. The plywood is manufactured in a variety of thicknesses and sizes, depending on the specific requirements of the application.

Manufacturing Process of Film-Faced Plywood

The production of film-faced plywood involves several key steps, each contributing to the material's durability and performance.

-

Selection of Veneers: The process begins with the selection of high-quality veneers. The core veneers are usually made from hardwood species like birch, poplar, or eucalyptus, known for their strength and durability. The veneers are peeled from logs, dried, and sorted based on their quality.

-

Lamination: The dried veneers are then layered with the grains running perpendicular to each other. This cross-lamination process enhances the plywood's strength and dimensional stability, preventing it from warping or splitting. The layers are bonded together using waterproof adhesives, such as phenolic or melamine formaldehyde resin, which further enhances the plywood's moisture resistance.

-

Application of Phenolic Film: Once the core plywood is laminated, a phenolic film is applied to one or both sides of the board. The film is impregnated with phenolic resin, a synthetic polymer that provides excellent water and chemical resistance. The application of the film is done under heat and pressure, ensuring a strong bond between the film and the plywood surface.

-

Cutting and Finishing: After the film has been applied, the plywood sheets are cut to the desired dimensions and sanded to achieve a smooth finish. The edges of the plywood may also be sealed with a waterproof coating to prevent moisture from penetrating the core.

Advantages of Film-Faced Plywood

Film-faced plywood offers several advantages that make it a preferred choice in construction and industrial applications.

-

Water and Moisture Resistance: One of the primary benefits of film-faced plywood is its excellent resistance to water and moisture. The phenolic film creates a waterproof barrier that prevents water from penetrating the plywood, making it ideal for use in environments where the material is exposed to moisture, such as in concrete formwork or outdoor structures.

-

Durability and Strength: The cross-laminated structure of film-faced plywood, combined with the use of high-quality veneers and strong adhesives, gives it exceptional strength and durability. It can withstand heavy loads and impacts, making it suitable for demanding applications like scaffolding, flooring, and heavy-duty packaging.

-

Smooth Surface Finish: The phenolic film provides a smooth, hard surface that is resistant to scratches, abrasions, and chemicals. This smooth finish is particularly beneficial in concrete formwork, where it ensures that the concrete surfaces are smooth and free of defects.

-

Reusability: Film-faced plywood is known for its high reusability, particularly in concrete formwork. It can be used multiple times without losing its structural integrity or surface quality, making it a cost-effective option for construction projects.

-

Ease of Maintenance: The smooth, non-stick surface of film-faced plywood is easy to clean and maintain. This is especially important in applications like concrete formwork, where the plywood must be cleaned after each use to ensure consistent performance.

Applications of Film-Faced Plywood

Film-faced plywood is used in a wide range of applications, thanks to its durability, moisture resistance, and smooth finish. Some of the most common applications include:

-

Concrete Formwork: One of the most widespread uses of film-faced plywood is in concrete formwork. The plywood's smooth surface ensures that the concrete casts are free of imperfections, while its strength and durability allow it to withstand the pressures exerted by wet concrete. Because it can be reused multiple times, film-faced plywood is a cost-effective choice for large construction projects.

-

Flooring: Film-faced plywood is often used in flooring applications, particularly in areas that require a durable, moisture-resistant surface. It is commonly used as a subfloor in buildings or as a temporary floor in construction sites.

-

Scaffolding Platforms: The strength and moisture resistance of film-faced plywood make it ideal for use in scaffolding platforms. It can support the weight of workers and materials, and its smooth surface provides a safe, stable platform.

-

Vehicle and Container Flooring: Film-faced plywood is also used in the flooring of vehicles and shipping containers. Its durability and resistance to wear make it suitable for high-traffic areas, while its moisture resistance ensures that it can withstand exposure to the elements.

-

Furniture and Cabinetry: In the furniture and cabinetry industry, film-faced plywood is used to create durable, moisture-resistant surfaces. Its smooth finish and strength make it a popular choice for worktops, cabinets, and other furniture components.

-

Outdoor Structures: Due to its resistance to moisture and weathering, film-faced plywood is often used in the construction of outdoor structures such as sheds, kiosks, and temporary buildings.

Conclusion

Film-faced plywood is a versatile and durable material that has become a staple in the construction and industrial sectors. Its unique combination of strength, moisture resistance, and smooth finish makes it suitable for a wide range of demanding applications, from concrete formwork to scaffolding and flooring. As construction technologies continue to evolve, film-faced plywood remains a reliable and cost-effective solution, meeting the needs of modern builders and engineers. Whether used in large-scale construction projects or specialized industrial applications, film-faced plywood proves its worth time and again as a material that can withstand the rigors of tough environments while delivering consistent performance.

- Vietnam: Wood product exports recover but problems remain

- US hardwood flooring imports fell more than 10% in January

- The decline in the construction industry affects European laminate flooring sales

- The European woodworking industry expressed great concern about the EUDR

- Plywood Container Flooring: The Backbone of Modern Shipping Introduction

- Packing Plywood: A Reliable Material for Secure Shipping

- Flexible Plywood: Versatility in Design and Construction