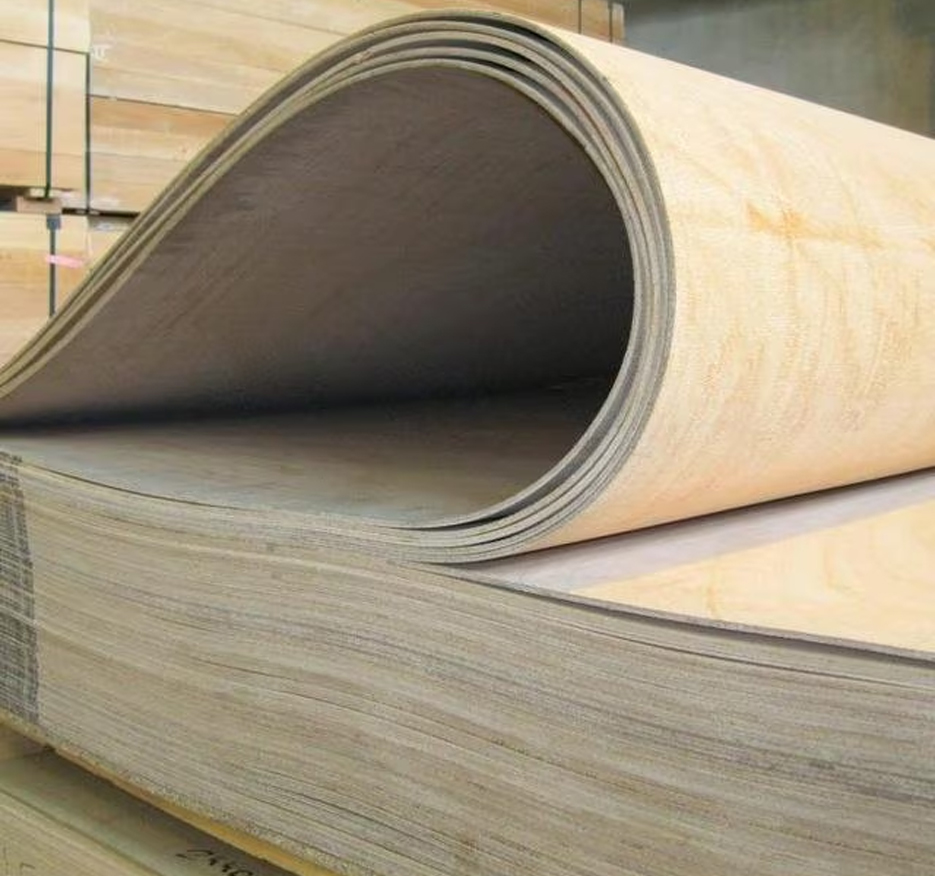

Flexible Plywood: Versatility in Design and Construction

What is Flexible Plywood?

Flexible plywood is a type of plywood specifically engineered to bend and curve easily, making it ideal for projects that require non-linear, flowing shapes. Unlike standard plywood, which is rigid and difficult to bend, flexible plywood is designed with thin layers of veneer that allow it to conform to a wide range of shapes without cracking or splitting.

The flexibility of this plywood is achieved by using veneers with grains that are oriented in a particular way, often with fewer layers than traditional plywood. These veneers are typically made from softwoods like poplar or birch, which are known for their pliability. Flexible plywood is available in various thicknesses, with thinner sheets offering greater flexibility for tighter curves and thicker sheets providing more structural support for larger arcs.

Manufacturing Process of Flexible Plywood

The production of flexible plywood involves a carefully controlled process to ensure that the final product can bend and curve as required without compromising its strength or integrity.

-

Selection of Veneers: The process begins with the selection of high-quality veneers. Softwoods like poplar or birch are commonly used due to their inherent flexibility and light weight. The veneers are typically thinner than those used in standard plywood, which contributes to the material's ability to bend.

-

Veneer Orientation: The key to flexible plywood's bendability lies in the orientation of its veneers. In standard plywood, the veneers are cross-laminated, with each layer's grain running perpendicular to the next. In flexible plywood, however, the veneers are often oriented with the grain running in the same direction, or in a manner that promotes flexibility. This arrangement allows the plywood to bend along the direction of the grain.

-

Bonding and Pressing: The veneers are bonded together using strong, flexible adhesives that maintain the integrity of the plywood even when it is bent. The layers are pressed under controlled heat and pressure to create a solid, uniform sheet that retains its flexibility. The pressing process is critical to ensuring that the plywood can bend without delaminating or splitting.

-

Cutting and Finishing: After the plywood has been pressed, it is cut into sheets of the desired size and thickness. The edges of the plywood may be sanded or sealed to prevent splintering and to maintain a smooth finish when the plywood is bent.

Advantages of Flexible Plywood

Flexible plywood offers several advantages that make it a valuable material in design and construction.

-

Ease of Bending and Shaping: The most significant advantage of flexible plywood is its ability to bend and curve with ease. This makes it ideal for creating complex, non-linear shapes that would be difficult or impossible to achieve with standard plywood or solid wood. Designers can use flexible plywood to create flowing, organic forms that add a unique aesthetic to their projects.

-

Lightweight and Strong: Despite its flexibility, flexible plywood is strong and durable. It can support structural elements and withstand the stresses of bending without cracking or losing its integrity. Additionally, it is lightweight, making it easier to handle and install in various applications.

-

Versatility: Flexible plywood is highly versatile and can be used in a wide range of applications, from furniture making to interior design and architectural projects. Its ability to conform to different shapes makes it suitable for both decorative and functional purposes.

-

Smooth Surface Finish: Flexible plywood typically has a smooth surface that can be easily finished with veneers, laminates, or paints. This allows designers to achieve a polished, professional look in their projects, whether they are creating curved furniture pieces or architectural features.

-

Cost-Effective: Compared to other materials that can achieve similar curved effects, such as fiberglass or molded plastic, flexible plywood is relatively inexpensive. It offers a cost-effective solution for projects that require curved elements, without sacrificing quality or aesthetics.

Applications of Flexible Plywood

Flexible plywood is used in a variety of applications across different industries, thanks to its unique ability to bend and curve. Some of the most common applications include:

-

Furniture Design: One of the most popular uses of flexible plywood is in furniture design. It is ideal for creating curved furniture pieces, such as chairs, tables, and shelving units, that feature flowing, organic lines. Flexible plywood allows designers to push the boundaries of traditional furniture shapes, resulting in innovative and modern designs.

-

Interior Design: In interior design, flexible plywood is often used to create curved walls, ceilings, and partitions. It can be used to build custom cabinetry, wall panels, and decorative elements that add a sense of movement and fluidity to a space. Its flexibility allows it to conform to the contours of a room, making it perfect for creating seamless, integrated designs.

-

Architectural Features: Architects use flexible plywood to create curved architectural features, such as arches, columns, and facades. It is also used in the construction of spiral staircases, where its ability to bend and maintain structural integrity is essential. Flexible plywood allows architects to incorporate curves into their designs, adding a dynamic visual element to buildings.

-

Marine and Automotive Industries: Flexible plywood is also used in the marine and automotive industries for constructing curved panels and components. In boats, it is used to create curved hulls and interiors, while in automobiles, it can be used for dashboards and other interior elements that require a curved shape.

-

Exhibition and Stage Design: In exhibition and stage design, flexible plywood is used to create custom displays, sets, and props. Its ability to bend and curve makes it ideal for creating dynamic, eye-catching designs that capture attention. Flexible plywood is often used in temporary installations where the design needs to make a bold visual statement.

Conclusion

Flexible plywood is a remarkable material that has transformed the possibilities of design and construction. Its unique ability to bend and curve without compromising strength or durability makes it an invaluable tool for architects, designers, and builders who seek to create innovative and visually striking projects. From furniture and interior design to architectural features and industrial applications, flexible plywood offers a versatile, cost-effective solution for achieving complex, curved shapes that enhance the aesthetics and functionality of any project. As design trends continue to evolve, flexible plywood will remain a key material in the creation of fluid, organic forms that push the boundaries of traditional construction methods.

- Vietnam: Wood product exports recover but problems remain

- US hardwood flooring imports fell more than 10% in January

- The decline in the construction industry affects European laminate flooring sales

- The European woodworking industry expressed great concern about the EUDR

- Plywood Container Flooring: The Backbone of Modern Shipping Introduction

- Film Faced Plywood,Known by various names such as formwork plywoo

- Packing Plywood: A Reliable Material for Secure Shipping